Why bar bending schedule of the slab is done?

Bar Bending schedule helps to estimate the quantity of rebar required in a structure. Here, we will see the bar bending schedule of two way Slab. We will see step-by-step calculations with a video at the last of the numerical.

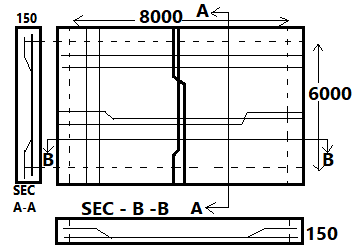

Numerical Example of Bar Bending Schedule of Two way Slab

Given,

1) Two way slab:-

8080 x 6080 x 150

Clear Cover = 40 mm

Effective Length and Width,

8000x6000x150 mm = 26’ x 19.5’ x 6”

2) Main bar:-

12 mm @100 c/c = 4”

Given,

3) Dist. bar:-

12 mm @150 c/c = 6”

4) Development length:-

Ld = 40 d (Where d is dia. Of rebar)

5) Top extra bar

8 mm @150 c/c (Both direction)

Calculation of Bar Bending Schedule (BBS) of Slab

1) No of main bar & distribution bar:-

No. of main bar = 8000/100+ 1 = 81 nos

No. of distribution bar & Distribution bar:-

= 6000/150+ 1 = 41 nos

2) Cutting length of main bar & distribution bar:-

Formula:- Cutting length = clear span + (2 x Ld) + (1 x 0.42D)

– (45o bend x 2)

Where,

Ld is development length. Generally Provided 40d to 50d. ie. 40 times of diameter of rebar.

For 45 degree bend we subtract 1 times the diameter of the steel bars.

a) Cutting length main bar = 6000 + (2 x 40 x 12) + (1 x 0.42 x 88) – (12 x 2) = 6972.96mm = 6.97 m.

b) Cutting length distribution bar,

= 8000 + (2 x 40 x 12) + (1 x 0.42 x 88) – (12 x 2) = 8972.96 mm = 8.97 m

3) Top extra bar:-

a) No. of long bar & short bar:-

No. of long bar = (6000/5)/150 + 1 = 9 nos x 2 = 18no.

No. of short bar=(8000/5) /150 + 1= 12 nos x 2 = 24 no.

b) Cutting length of long bar & short bar:-

Cutting length long bar = 8000 + (2 x 40 x 8) = 8640 mm = 8.64 m

Cutting length short bar = 6000 + (2 x 40 x 8) = 6640 mm = 6.64 m

Bar Bending Schedule of two-way slab Table

| Description | Dia of bar | Nos | L (m) | Wt/m | Qty (kg) {(d*d*L)/162.25} |

| Main bar | 12 | 81 | 6.97 | 0.89 | 502.46 |

| Distribution bar | 12 | 41 | 8.97 | 0.89 | 327.31 |

| Short extra bar | 8 | 24 | 6.64 | 0.4 | 63.74 |

| Long extra bar | 8 | 18 | 8.64 | 0.4 | 62.21 |

| = 955.75 Kg. |

Some Frequently Asked Questions

How much should be minimum thickness of slab as per IS 456?

Ans:- AS per IS 456 the minimum thickness of the concrete slab should not be less the 125 mm or 5 inches or L/30, where L is the unsupported span of the concrete slab. We have to provide the depth or thickness which ever is greater.

How much should be maximum thickness of slab?

The maximum thickness of the slab depends upon the design load on the structure. There is no limit mentioned in the code but the thickness of the slab should be provided such that it will be safe as well as economical.

How much should be Minimum reinforcement in slab?

The minimum reinforcement in the slab should not be less than 0.12% for HYSD steel bars and 0.15% for Mild steel bars. The percentage of the steel bars should be of the cross-sectional area of the slab.

Watch Video

Read Also:-

Calculate weight of steel bar | Quantity of steel bar in circular slab

Steel bar weight Calculator for length in feet With total Cost

Bar bending schedule of square or rectangular Column Calculator